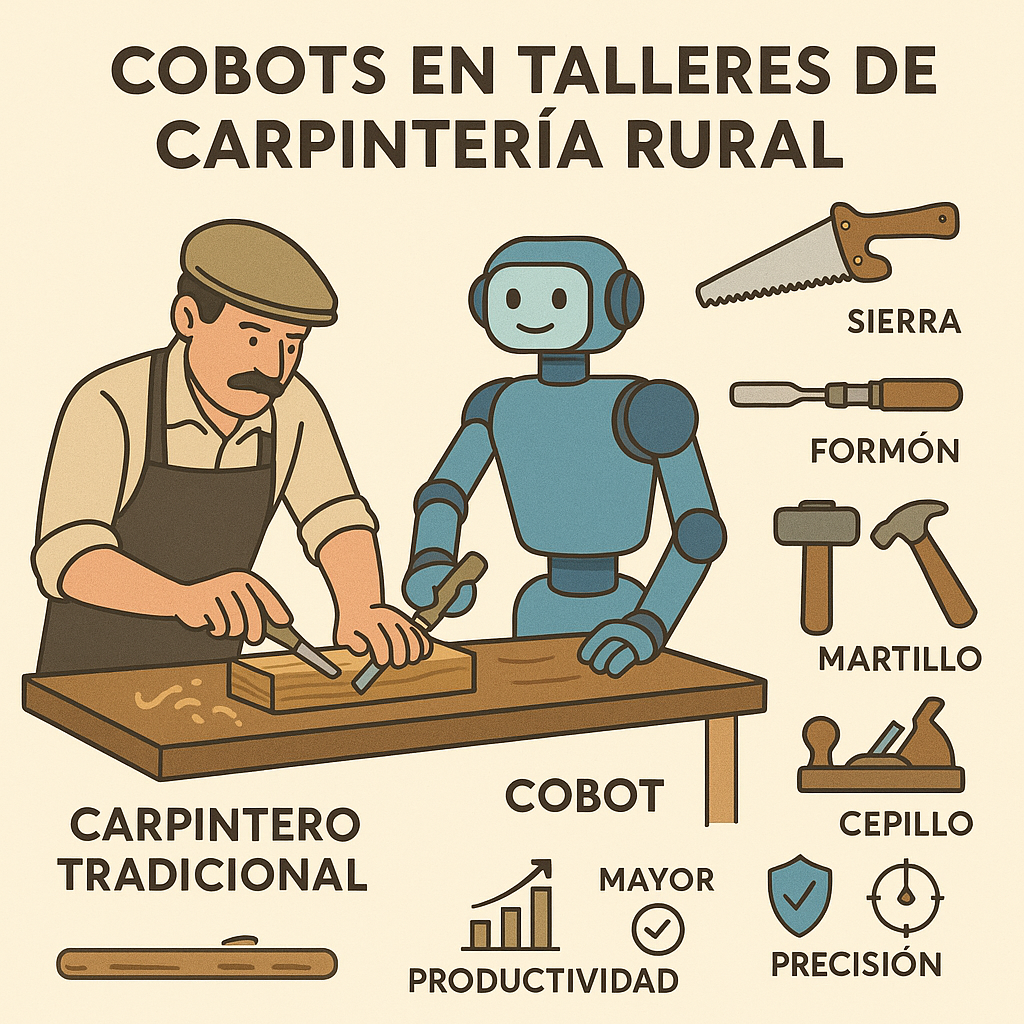

Digitalization is not at odds with craftsmanship. On the contrary, in sectors such as rural carpentry, the integration of collaborative robots (cobots) can make the difference between merely surviving and growing. Today, small carpentry workshops can automate repetitive or physically demanding tasks without giving up traditional know-how.

Unlike classic industrial robots, cobots are designed to work hand in hand with people, without the need for safety cages. They are more compact, affordable, and adaptable, making them a realistic option for rural workshops that want to become more competitive without losing their identity.

What tasks can a cobot perform in carpentry?

Cobots do not replace the creativity or skill of the carpenter, but they can take on repetitive or physically demanding tasks that consume time and energy. Thanks to their precision and ease of programming, these collaborative robots can be seamlessly integrated into the workshop’s daily operations, freeing up time for what really matters: craftsmanship.

Tasks that a cobot can perform in a carpentry workshop include:

Loading and unloading parts into CNC (Computer Numerical Control) machines. CNC machines are automated tools that use computer programs to control and guide cutting tools, enabling the precise manufacturing of complex parts.

Uniform application of varnishes or adhesives.

Automatic sanding of wooden surfaces.

Repetitive cutting of pieces with high precision.

Handling and palletizing in small warehouses.

Concrete Benefits

Beyond technology, what truly matters are the results. Incorporating a cobot into a rural carpentry workshop not only improves efficiency but also takes care of the people who make it possible. From reducing physical strain to enhancing the quality of the final product, the benefits are tangible and sustainable, such as:

Increased workshop productivity.

Reduced physical effort for workers, improving working conditions.

Greater precision and repeatability in critical processes.

Fewer errors and less material waste.

Ability to operate full shifts without human fatigue.

What Do You Need to Get Started?

Taking the first step toward automation doesn’t require major investments or advanced technical knowledge. With a small assessment of the current process and some basic training, any workshop can begin integrating cobots gradually and tailored to its real needs. You will need:

A brief analysis of your workflow.

Identification of repetitive, manual, or physically demanding tasks.

Staff training in safety and basic cobot handling.

Evaluation of digitalization support programs or proof-of-concept testing.

Robots don’t replace the craftsman—they accompany them. If you run a workshop and want to improve productivity without losing your essence, cobots can be your best ally.

DIGIS3 Support

You are not alone in this process. At DIGIS3 we provide personalized support to ensure that the integration of cobots is a success. We analyze your case, help you find the right solution, and connect you with available resources and funding so that digital transformation is both accessible and effective.

Free digital maturity assessment.

Test Before Invest laboratory.

Basic and advanced training.

Advice on financing opportunities.

📩 Contact us at info@digis3.eu to modernize your workshop and keep your machines running at full capacity.